AI in Manufacturing Use cases, Tech, Benefits, Challenges and more

The manufacturing industry has long struggled with inefficiencies, production errors, and high maintenance costs. Manual processes, human errors, and the lack of real-time insights often lead to increased expenses, lower quality, and missed opportunities. One of the most critical challenges in manufacturing is detecting and resolving faults in the production process. Traditional methods rely on outdated procedures that fail to identify issues accurately, resulting in delays and costly errors.

Artificial Intelligence (AI) is transforming the manufacturing landscape by addressing these challenges head-on. With AI-driven fault detection, predictive maintenance, and automated quality control, manufacturers can significantly reduce errors and optimize production efficiency. AI’s ability to analyze vast datasets enables better decision-making, resource allocation, and inventory management. According to Precedence Research, the AI in manufacturing market was valued at USD 3.8 billion in 2022 and is expected to surge to approximately USD 68.36 billion by 2032, growing at a staggering 33.5% CAGR from 2023 to 2032.

This article explores AI’s growing role in manufacturing, showcasing its game-changing applications that enhance efficiency, precision, and overall operational success. As manufacturers embrace AI-driven innovations, they unlock new opportunities to streamline production, reduce costs, and drive the industry into the future.

AI in Manufacturing

AI in manufacturing refers to the integration of artificial intelligence technologies to optimize processes, enhance efficiency, and improve decision-making. By leveraging AI-driven automation, manufacturers can reduce human errors, increase productivity, and streamline operations. AI applications range from predictive maintenance and quality control to supply chain optimization and workforce management.

How AI is Reshaping Manufacturing

AI is transforming manufacturing by enabling smarter decision-making and real-time process optimization. It plays a critical role in various areas, from product development to logistics and workforce planning.

- Research and Development (R&D): AI-powered predictive analytics analyze market trends, consumer behavior, and historical data to enhance product innovation and demand forecasting.

- Production and Operations: AI-driven machine vision systems detect defects in real-time, while predictive maintenance minimizes unplanned downtime and reduces repair costs.

- Supply Chain and Logistics: AI algorithms optimize inventory levels, predict demand patterns, and enhance logistics by reducing transportation costs and improving delivery times.

Workforce and HR Optimization

AI improves workforce management by automating repetitive tasks, enhancing employee engagement, and optimizing resource allocation. These advancements allow organizations to better manage their workforce while reducing operational inefficiencies.

- Recruitment and HR: AI-powered tools streamline hiring processes by screening resumes, conducting initial interviews, and assessing candidate suitability. AI-driven analytics also help HR teams predict employee performance and retention trends.

- Employee Engagement: AI-driven sentiment analysis helps identify workplace concerns early, improving employee satisfaction and retention. Automated feedback mechanisms provide actionable insights, helping companies maintain a motivated workforce.

- Payroll Automation: AI-based attendance systems using biometric or facial recognition automate payroll calculations, ensuring accuracy and compliance with labor laws. These systems also detect attendance trends, helping businesses optimize workforce scheduling and reduce overtime costs.

AI in Sales, Marketing, and Finance

AI enhances business operations by optimizing financial planning, cost management, and customer engagement strategies. The ability to process large volumes of data enables organizations to make more informed decisions, leading to improved profitability and customer satisfaction.

- Sales and Marketing: AI-driven insights enable personalized marketing campaigns, improve lead generation, and enhance customer interactions through chatbots and recommendation systems. AI tools also analyze consumer behavior, allowing businesses to adjust pricing strategies and maximize revenue.

- Finance and Cost Management: AI algorithms analyze spending patterns, optimize procurement strategies, and identify cost-saving opportunities to improve financial efficiency. Automated budgeting tools help manufacturers predict expenses, allocate funds more effectively, and prevent unnecessary spending.

- Payroll Processing: AI automates wage calculations, tax compliance, and attendance tracking, ensuring error-free payroll management. AI-powered systems can also identify potential fraud, such as false attendance logging, and help maintain transparency in salary distribution.

AI’s role in manufacturing continues to grow, driving efficiency, reducing costs, and fostering innovation across all departments. Its ability to process vast amounts of data and provide actionable insights positions AI as a transformative force in modern manufacturing.

AI Use Cases in Manufacturing

In today’s manufacturing landscape, Artificial Intelligence (AI) is a transformative force, driving the industry towards greater efficiency, precision, and innovation. AI’s integration across various departments is reshaping operations, resource management, and decision-making. From predictive analytics to intelligent automation, AI is revolutionizing how manufacturers design products, manage supply chains, and ensure quality control. As a result, AI adoption is enhancing productivity while reducing operational costs, errors, and downtime. Here are some notable AI use cases in manufacturing:

Market Trends Research

AI enhances market trends research by analyzing extensive data sets to uncover patterns and emerging trends. It predicts consumer demand, optimizes supply chains, and improves product development by extracting insights from both structured and unstructured data. AI-driven analytics enable research departments to make informed decisions, enhance forecasting accuracy, and remain competitive in a rapidly changing market.

- Machine learning algorithms automate data collection and analysis, saving time and resources for research teams.

- Natural language processing (NLP) extracts insights from industry reports, articles, and consumer feedback.

- AI-powered tools help identify market shifts early, allowing manufacturers to adapt and innovate proactively.

Identifying Consumer Preferences

AI supports the manufacturing research department by analyzing large datasets of consumer preferences, including online reviews, social media comments, and purchasing history. Machine learning algorithms can detect trends, sentiments, and emerging preferences, aiding manufacturers in making data-driven decisions on product design, features, and marketing strategies.

- AI-powered sentiment analysis deciphers consumer emotions and expectations.

- Personalization engines tailor product offerings to specific market segments.

- Real-time data analysis allows manufacturers to respond swiftly to changing consumer behaviors.

Historical Data Analysis

AI enhances historical data analysis in manufacturing by automating the extraction, cleansing, and organization of data, making it easier for researchers to access past records. Machine learning models can detect patterns and anomalies in historical data, aiding researchers in making informed decisions and optimizing processes.

- Predictive analytics forecasts future trends based on historical data, enabling proactive decision-making.

- AI-driven insights help refine production techniques and enhance operational efficiency.

- NLP extracts relevant information from textual historical documents, boosting research capabilities.

Innovation and Ideation

AI plays a crucial role in driving innovation and ideation within the manufacturing sector. It analyzes extensive datasets to identify emerging trends, market needs, and competitor strategies. By drawing insights from sources like scholarly articles, patents, and consumer feedback, AI acts as a catalyst for developing new ideas and solutions.

- AI-driven design thinking accelerates prototype development and experimentation.

- Predictive analytics anticipates potential risks and optimizes resource allocation.

- AI fosters collaboration by connecting researchers with relevant industry insights.

Materials Research

AI optimizes materials research in manufacturing by enhancing resource utilization. It determines the precise amount of materials needed for specific applications, reducing waste and promoting sustainability. AI technologies expedite the discovery of new materials by predicting their properties using existing data.

- AI-driven simulations model material behavior under various conditions.

- Automated testing processes reduce time and costs associated with material research.

- Advanced analytics help identify alternative materials for enhanced durability and efficiency.

Designing

AI significantly contributes to the design process in manufacturing. It uses advanced algorithms to analyze large datasets and simulate different design scenarios, enabling engineers to optimize product designs for performance, cost-effectiveness, and sustainability.

- Machine learning models identify innovative design patterns and trends.

- AI-powered CAD (Computer-Aided Design) tools enhance precision and efficiency.

- Generative design automates complex design processes, accelerating product development.

Defect Detection

Many assembly lines lack robust defect detection systems, often relying on basic setups that require skilled engineers to manually program them. These systems tend to generate numerous false alarms, necessitating time-consuming manual inspections. By incorporating artificial intelligence and self-learning capabilities, manufacturers can save time and reduce false alarms, thereby enhancing efficiency.

- AI-powered vision systems detect defects in real time with higher accuracy.

- Automated quality control reduces human error and ensures consistent product quality.

- Deep learning models continuously improve defect detection algorithms over time.

Assembly Line Integration

An assembly line is a manufacturing process where partially assembled products move through a series of workstations in a specific sequence. In modern manufacturing, AI-automated assembly lines are common, with machines performing most tasks and requiring minimal human intervention.

- AI-driven automation ensures precision and reduces errors.

- Robotics-powered assembly lines optimize efficiency and speed.

- Machine learning algorithms adapt to production variations, enhancing flexibility.

Predictive Analytics

AI algorithms can forecast equipment failures or malfunctions by analyzing sensor data and historical maintenance records. By identifying patterns and trends, manufacturers can proactively schedule maintenance activities, order spare parts in advance, and avoid costly unplanned downtime.

- Predictive maintenance reduces repair costs and prevents production delays.

- AI-based diagnostics improve machinery reliability and efficiency.

- Data-driven insights help optimize equipment performance and longevity.

Real-Time Monitoring and Analysis

AI technology enables real-time monitoring of production lines, collecting data from sensors, machines, and other sources. This data is then analyzed to identify bottlenecks, optimize processes, and improve overall efficiency.

- AI-driven monitoring ensures quick detection of anomalies.

- Automated adjustments enhance production efficiency and quality control.

- Data analytics help manufacturers make informed operational decisions.

Process Optimization

AI techniques, such as machine learning, scrutinize production data to pinpoint inefficiencies and refine manufacturing processes. By evaluating factors like product cycle times, energy consumption, and material usage, AI algorithms can propose process enhancements.

- AI identifies production bottlenecks and suggests corrective actions.

- Optimization strategies lead to cost savings and improved resource utilization.

- AI-powered automation streamlines workflows for higher efficiency.

Energy Management

AI algorithms enhance energy usage in manufacturing facilities by analyzing real-time data and identifying energy wastage patterns. By recommending energy-saving strategies and optimizing equipment operations, manufacturers can lower energy costs and bolster sustainability efforts.

- Smart energy management systems improve efficiency and reduce waste.

- AI-powered predictive models help manufacturers meet environmental regulations.

- Automated energy adjustments optimize equipment performance for sustainability.

Supply Chain Optimization

AI-driven analytics refine supply chain operations by examining various data sources, including demand forecasts, production capacities, and inventory levels. Manufacturers can make informed decisions to streamline procurement, inventory management, and distribution processes.

- AI improves demand planning and supply chain resilience.

- Automated inventory tracking reduces shortages and excess stock.

- AI-driven logistics enhance delivery efficiency and minimize costs.

Demand Forecasting

AI-powered demand forecasting models leverage historical sales data, emerging market trends, and external factors to accurately predict future demand. Manufacturers can use these forecasts to align production and inventory levels with expected demand.

- AI-driven forecasting reduces overproduction and stock shortages.

- Real-time demand tracking enhances supply chain agility.

- Data-driven insights improve market responsiveness and customer satisfaction.

Warehouse Management

AI offers diverse automation opportunities in warehouse management. With a continuous flow of data, manufacturers can improve inventory oversight and optimize logistics. This automation cuts warehouse management costs and boosts productivity.

- AI-powered robots streamline warehouse operations.

- Automated tracking systems enhance inventory accuracy.

- Smart logistics improve storage efficiency and order fulfillment.

Fair Compensation Management

Manufacturing facilities often reward employees with bonuses for working extra hours. However, accurately assessing and ensuring fair compensation for overtime can be a challenging task. AI-driven HR technology simplifies this process.

- AI automates overtime tracking and wage calculations.

- Smart payroll systems reduce errors in employee compensation.

- AI ensures compliance with labor laws and fair employee treatment.

Reporting

AI enhances manufacturing efficiency by automating data tracking, compliance reporting, and equipment performance analysis. It ensures regulatory adherence and proactive maintenance while improving workforce safety and operational insights.

- Automates compliance reporting and reduces manual effort

- Uses predictive analytics to identify potential safety risks

- Optimizes equipment maintenance through real-time data analysis

Personalization

AI-driven personalization tailors marketing efforts to individual customers by analyzing behavioral data. This approach enhances engagement, improves targeting accuracy, and increases conversions in the manufacturing industry.

- Customizes marketing messages based on customer preferences

- Utilizes predictive analytics for better audience segmentation

- Enhances customer experience with data-driven recommendations

Email Marketing

AI-powered email marketing optimizes communication with potential clients and partners in the manufacturing sector. Automated tools segment audiences, personalize messaging, and track engagement for effective lead nurturing.

- Automates email campaigns with AI-driven personalization

- Segments audiences based on industry, role, and interactions

- Analyzes engagement metrics to refine future marketing efforts

Copywriting

AI enhances copywriting by generating persuasive and engaging content for websites, product descriptions, and marketing materials. It ensures consistency in messaging while optimizing content for target audiences.

- Creates compelling product descriptions and promotional content

- Uses AI-driven insights to tailor messages for specific audiences

- Optimizes copy for SEO and brand visibility in manufacturing

Yield Optimization and Batch Analysis

AI improves yield optimization and batch analysis by analyzing production data, identifying inefficiencies, and making real-time adjustments. It enhances product quality, reduces waste, and maximizes efficiency across industries.

- Identifies production patterns affecting yield and quality

- Optimizes manufacturing parameters to minimize defects

- Enables real-time process adjustments for peak efficiency

Smart Energy Management

AI-driven smart energy management optimizes HVAC, lighting, and power consumption in manufacturing facilities. By analyzing usage patterns and external factors, AI reduces energy waste and lowers operational costs.

- Adjusts energy usage dynamically based on real-time data

- Reduces energy waste while maintaining operational efficiency

- Supports sustainability goals and regulatory compliance

Order Management

AI-driven order management streamlines the order-to-delivery cycle by automating processing, predicting demand, and optimizing resource allocation. This ensures efficient fulfillment and reduces errors.

- Automates order tracking and inventory management

- Predicts demand trends to optimize stock levels

- Enhances delivery efficiency by prioritizing critical orders

Additive Manufacturing

AI enhances 3D printing and additive manufacturing by improving design precision, optimizing material usage, and automating production. It enables faster prototyping and cost-effective customization.

- Enhances 3D printing precision and material efficiency

- Enables real-time adjustments for optimal production outcomes

- Reduces waste while allowing for complex design capabilities

Manufacturing is rapidly evolving with AI-driven innovations, improving efficiency, reducing costs, and enabling smarter decision-making. These advancements position manufacturers for long-term success in an increasingly competitive market.

Onegen’s AI Development Services for Manufacturing

Onegen delivers tailored AI solutions to revolutionize operations in the manufacturing sector. Our AI/ML consulting services empower manufacturers to elevate production efficiency, ensure quality control, and streamline supply chain management through automation and intelligent analytics. These solutions are designed to reduce operational friction, enhance decision‑making, and future‑proof manufacturing systems.

We specialize in developing Proof of Concepts (PoCs) and Minimum Viable Products (MVPs) to validate real‑world performance before scaling. Our generative AI tools automate repetitive tasks such as predictive maintenance and production planning, allowing engineers to focus on higher‑level strategy and innovation. With manufacturing‑specific fine‑tuning of large language models, our systems deliver industry‑relevant insights and integrate seamlessly with your existing technology infrastructure.

AI Solutions for Manufacturing

AI solutions developed by Onegen unify data‑driven intelligence with agile automation to improve key aspects of the manufacturing lifecycle. These systems consolidate and analyze data from multiple sources, empowering businesses to predict machine failures, reduce downtime, and optimize production schedules.

- Predictive maintenance to minimize costly equipment breakdowns

- Automated quality checks to uphold consistent production standards

- Smart production and logistics planning to improve workflow and delivery

- Integrated systems to centralize decision‑making and reduce human error

These AI‑enhanced tools help manufacturers operate with greater precision, reliability, and adaptability in a competitive market.

AI Agents and Copilots for Manufacturing

Our AI‑powered agents and copilots act as intelligent assistants across manufacturing operations. These tools handle time‑consuming tasks, generate insights, and support real‑time decision‑making across engineering, logistics, and operations.

- Adaptive copilots for real‑time production insights

- Natural language interfaces to access plant performance data

- AI‑generated reports for resource and planning optimization

- Human‑AI collaboration tools for enhanced operator decision‑making

By embedding these tools into existing workflows, manufacturers reduce delays, increase transparency, and streamline every phase of the production lifecycle.

Predictive Maintenance

AI‑enabled maintenance systems at Onegen are designed to proactively address equipment wear and performance issues. These systems rely on historical data, IoT sensor inputs, and real‑time analytics to detect anomalies early and avoid unexpected halts in production.

- Intelligent alerts based on predictive performance modeling

- Optimized maintenance schedules that prevent costly downtime

- Automated tracking of equipment health and diagnostics

- Maintenance planning based on production load and lifecycle

Predictive maintenance reduces costs, extends equipment life, and ensures production remains uninterrupted.

Quality Control

AI systems can dramatically enhance quality assurance by continuously monitoring product output and catching inconsistencies early. By learning from image data and production feedback, these systems maintain consistency while reducing the need for manual inspection.

- AI‑powered vision systems for detecting subtle defects

- Pattern recognition algorithms to maintain uniformity

- Real‑time feedback for process optimization

- Data‑driven performance scoring for design adjustments

This approach improves production consistency while saving time and operational effort.

Supply Chain Optimization

AI enhances the responsiveness and reliability of manufacturing supply chains. Onegen’s AI models track global logistics, vendor timelines, and material requirements to reduce disruptions and optimize delivery.

- Automated demand forecasting using real‑time and historical data

- Smart inventory planning to avoid overstock or shortages

- Intelligent procurement recommendations based on supplier reliability

- Logistics modeling for cost‑efficient transport and delivery

AI‑driven supply chains are resilient, adaptive, and more cost‑effective.

Production Planning

AI helps manufacturers dynamically adjust production schedules based on internal and external variables. These systems consider order volume, equipment availability, staffing, and raw material flow to make real‑time scheduling decisions.

- Centralized dashboards for real‑time visibility into operations

- Intelligent reallocation of labor and materials to match demand

- Rapid identification of delays or bottlenecks in production lines

- AI‑generated timetables based on order priority and capacity

This agility in planning allows businesses to respond faster to shifting market needs.

Process Automation

Onegen’s AI solutions automate routine, repetitive, and data‑heavy tasks. Automation reduces human errors, boosts speed, and ensures higher output consistency across all departments.

- Streamlined data entry and validation for operational accuracy

- Auto‑generated reports for faster decision cycles

- Workflow automation for scheduling, compliance, and resource allocation

- Integrated alerts for real‑time production milestones

Process automation enhances efficiency, letting staff focus on innovation and quality.

Defect Detection

Advanced AI vision systems are trained to detect even minor anomalies during manufacturing. These systems reduce product recalls and increase customer satisfaction by ensuring defects are caught early.

- Continuous image‑based monitoring of production lines

- Real‑time alerts when patterns suggest defect risks

- Automated categorization of detected issues for easier resolution

- Insights to help redesign processes for fewer errors

Reliable defect detection minimizes waste and supports higher product integrity.

Customer Segmentation and Targeting

AI isn’t limited to production—it’s a powerful tool for improving customer engagement. We use AI to analyze behavioral patterns, identify valuable segments, and recommend targeted marketing strategies.

- Segmentation based on product interaction and purchase behavior

- Personalized outreach for improved customer retention

- Upsell and cross‑sell opportunities using pattern analysis

- Targeted campaigns informed by regional and seasonal preferences

This data‑driven targeting helps manufacturers connect with customers more effectively and grow revenue.

Onegen’s AI development services empower manufacturers to enhance productivity, ensure quality, and optimize every step of their operations. Through AI agents, predictive systems, and intelligent planning tools, we help businesses transform challenges into growth opportunities. As AI continues to advance, our tailored solutions ensure that manufacturers stay ahead in a dynamic, technology‑driven landscape.

How AI Addresses Challenges in the Manufacturing Workflow

Manufacturers encounter various challenges at different stages of production, from initial design to final distribution. These challenges include fluctuating material costs, unpredictable demand, quality control issues, and equipment failures. AI-driven solutions help address these complexities through predictive analytics, automation, and real-time optimization. By integrating AI, manufacturers can enhance efficiency, reduce costs, and improve product quality while maintaining adaptability in a competitive market.

Product Design and Development

Challenge: Design iterations and optimization take time, delaying production and increasing costs.

Solution: AI-driven generative design explores multiple options rapidly, optimizing efficiency and cost-effectiveness. AI-powered simulation tools analyze material properties and stress factors to refine designs before production.

- Reduces design time by automating iterations

- Enhances innovation with AI-driven recommendations

- Lowers material waste by simulating design efficiency

Materials Procurement

Challenge: Fluctuating raw material costs and supply chain disruptions create uncertainty in production.

Solution: AI-driven predictive analytics forecast material costs and detect risks, enabling proactive procurement strategies. AI can also recommend alternative suppliers based on market conditions.

- Identifies cost-saving opportunities through market analysis

- Enhances supply chain resilience with predictive demand insights

- Automates procurement processes for timely material availability

Quality Control

Challenge: Difficulty in detecting defects in real time, leading to faulty products and higher rejection rates.

Solution: AI-powered vision systems automate inspections, identifying defects early and improving quality control. Machine learning models analyze past defect patterns to enhance accuracy.

- Increases precision in defect detection, reducing manual errors

- Speeds up inspections, preventing production delays

- Enhances compliance with quality assurance standards

Production Planning

Challenge: Unpredictable demand fluctuations and inefficient scheduling impact resource utilization.

Solution: AI-based demand forecasting and resource optimization align production with real-time market conditions. AI can also adjust schedules dynamically based on operational constraints.

- Optimizes workforce and machine utilization

- Reduces overproduction and stockpiling costs

- Adapts production plans based on real-time market demand

Engineering and Manufacturing

Challenge: Maintaining efficiency while reducing waste and ensuring high product quality.

Solution: AI optimizes production processes, reducing material waste and improving machine performance. AI-driven automation ensures consistent quality across production lines.

- Improves process efficiency by minimizing human errors

- Reduces downtime through AI-driven equipment monitoring

- Enhances energy efficiency with smart production adjustments

Quality Assurance

Challenge: Defects increase costs and slow down production, leading to customer dissatisfaction.

Solution: Machine learning models predict defects early, improving consistency and reducing rework. AI also recommends process modifications to enhance quality.

- Reduces production errors and associated costs

- Improves product reliability through continuous monitoring

- Enhances traceability in quality assurance reports

Warehousing and Distribution

Challenge: Inefficient inventory management and logistics delays cause stock shortages or excess inventory.

Solution: AI automates inventory tracking and optimizes delivery routes, reducing costs and improving supply chain efficiency. AI also predicts demand fluctuations for better stock management.

- Ensures optimal inventory levels by preventing overstocking

- Enhances logistics planning with AI-driven route optimization

- Reduces warehousing costs with automated stock monitoring

Sales and Marketing

Challenge: Difficulty in targeting the right customers and optimizing sales strategies.

Solution: AI analyzes customer behavior, preferences, and purchasing patterns to enable personalized marketing and smarter pricing strategies. AI also predicts market trends for product positioning.

- Increases sales conversion rates through targeted campaigns

- Enhances customer engagement with personalized recommendations

- Automates competitive pricing adjustments based on market trends

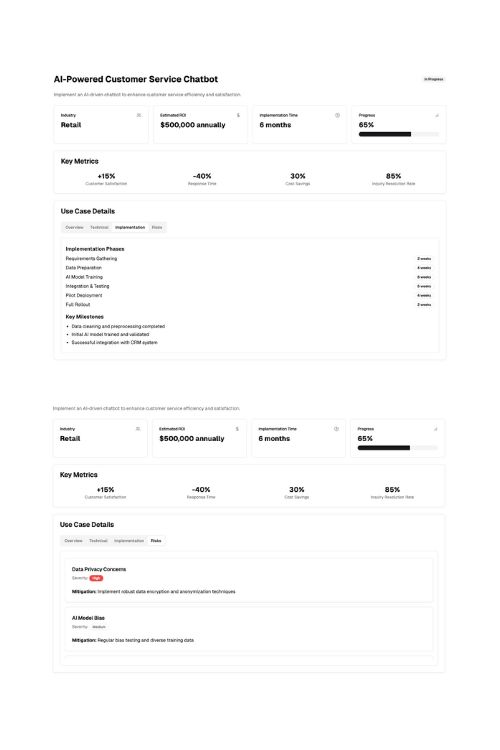

Customer Service

Challenge: Handling large volumes of inquiries efficiently without increasing support costs.

Solution: AI-powered chatbots and virtual assistants provide instant responses, improving customer satisfaction and reducing workload on human agents. AI-driven sentiment analysis helps address customer concerns proactively.

- Enhances customer experience with 24/7 automated support

- Reduces response time for common queries and complaints

- Improves customer retention with AI-driven insights

Maintenance and Upkeep

Challenge: Unexpected equipment failures cause costly downtime and disrupt production schedules.

Solution: AI-driven predictive maintenance forecasts breakdowns, enabling proactive repairs and reducing downtime. AI can also suggest optimal maintenance schedules based on usage patterns.

- Extends equipment lifespan with proactive servicing

- Reduces unexpected failures, ensuring continuous operations

- Cuts maintenance costs by avoiding unnecessary repairs

Continuous Improvement

Challenge: Identifying inefficiencies and areas for innovation to stay competitive.

Solution: AI-powered analytics provide data-driven insights to refine processes and drive long-term improvements. AI also suggests new technologies and automation strategies to enhance productivity.

- Identifies performance bottlenecks through real-time monitoring

- Supports innovation with AI-driven process enhancements

- Optimizes manufacturing strategies for long-term success

By integrating AI into manufacturing, companies can overcome these challenges, improving efficiency, quality, and overall operational effectiveness. AI-driven automation, predictive analytics, and real-time monitoring enable manufacturers to streamline their workflows and stay ahead in a competitive market.

How can AI be implemented in the manufacturing workflow for enhanced efficiency and innovation?

Integrating AI into manufacturing requires a structured approach to maximize efficiency and foster innovation. AI-driven automation, predictive analytics, and intelligent monitoring can enhance production quality, reduce downtime, and optimize resource utilization. A well-planned AI strategy ensures seamless integration, long-term sustainability, and maximum return on investment.

Set Clear Objectives

Clearly defining AI adoption goals is essential for aligning technology with business priorities. Setting measurable objectives ensures AI is implemented effectively, leading to improved efficiency, cost savings, and better decision-making in production.

- Identify key areas where AI can enhance operations and reduce inefficiencies.

- Define success metrics, such as improved product quality or reduced downtime.

- Align AI implementation with long-term business growth and sustainability strategies.

Evaluate Current Processes

A thorough assessment of existing workflows helps manufacturers pinpoint inefficiencies and determine where AI can create the most impact. Identifying bottlenecks ensures AI solutions are applied strategically for maximum benefit.

- Map out end-to-end manufacturing processes to detect weak points.

- Analyze manual and repetitive tasks that AI can automate for better efficiency.

- Assess data availability and quality to determine AI readiness and integration feasibility.

Data Collection and Integration

AI relies on high-quality, real-time data for accurate decision-making. Integrating data from multiple sources allows manufacturers to implement predictive analytics and automation for improved operational performance.

- Aggregate data from IoT sensors, production systems, and supply chains for analysis.

- Utilize cloud-based platforms to store and process large datasets efficiently.

- Implement AI-driven analytics to extract actionable insights from collected data.

Invest in Infrastructure and Technology

A strong technological foundation is necessary for AI deployment. Upgrading hardware, software, and computing resources ensures AI solutions run efficiently and integrate seamlessly into manufacturing operations.

- Modernize legacy systems to support AI-based automation and decision-making.

- Implement AI-powered analytics tools to optimize production and quality control.

- Adopt IoT and cloud computing to enhance real-time monitoring and data processing.

Develop AI Expertise

Building AI expertise within the workforce is crucial for long-term success. Manufacturers can upskill employees, hire AI professionals, or collaborate with AI specialists to ensure smooth adoption and operation of AI technologies.

- Offer AI training programs to educate employees on new systems and processes.

- Partner with AI experts to develop tailored solutions for manufacturing needs.

- Foster a culture of innovation where employees embrace AI-driven improvements.

Start with Pilot Projects

Launching small-scale AI projects allows manufacturers to assess feasibility and measure impact before full-scale implementation. Pilot programs help fine-tune AI applications and minimize risks.

- Implement AI in targeted areas, such as predictive maintenance or quality control.

- Monitor pilot project outcomes to refine AI strategies before broader deployment.

- Scale AI solutions gradually based on pilot success and operational requirements.

Select Suitable AI Technologies

Choosing the right AI technologies ensures that manufacturers maximize efficiency and innovation. AI applications, such as machine learning and computer vision, can enhance production processes and quality assurance.

- Deploy machine learning algorithms for predictive maintenance and efficiency tracking.

- Use AI-powered computer vision for real-time defect detection in production lines.

- Implement natural language processing (NLP) for AI-driven communication in operations.

Integrate with Existing Systems

Seamless integration with ERP, MES, and supply chain management tools ensures AI operates efficiently within existing workflows. AI-enabled systems enhance automation and improve overall productivity.

- Connect AI solutions with enterprise software for real-time data sharing.

- Ensure compatibility between AI applications and current manufacturing tools.

- Automate production planning and monitoring through AI-powered systems.

Employee Training and Change Management

Successful AI adoption requires employee readiness and engagement. Training programs help workers understand AI’s role, reducing resistance and improving collaboration between humans and machines.

- Conduct hands-on AI training to familiarize employees with new technologies.

- Address workforce concerns by demonstrating AI’s role in enhancing job functions.

- Promote AI as a tool that supports employees rather than replacing them.

Scale Up Implementation

After successful pilot testing, expanding AI across manufacturing workflows enhances efficiency and profitability. A phased approach ensures smooth scaling and minimizes operational disruptions.

- Extend AI implementation to multiple production sites and processes.

- Automate supply chain logistics with AI-driven forecasting and inventory management.

- Continuously monitor and refine AI models to optimize performance at scale.

Continuous Monitoring and Improvement

AI systems require continuous monitoring to remain effective. Regular evaluations and updates help manufacturers optimize AI-driven processes for long-term efficiency and adaptability.

- Track AI system performance using real-time data analytics.

- Improve AI algorithms based on operational feedback and evolving business needs.

- Implement adaptive AI strategies that evolve with changing production demands.

Cybersecurity Measures

AI-driven systems process sensitive manufacturing data, making cybersecurity a priority. Strong security measures prevent cyber threats and ensure the integrity of AI-powered operations.

- Deploy advanced encryption and multi-layered security for AI applications.

- Conduct regular security audits to identify and mitigate vulnerabilities.

- Implement access control measures to protect AI-driven automation systems.

Compliance and Regulations

Adhering to industry regulations and ethical guidelines is crucial for AI implementation in manufacturing. Compliance ensures transparency, accountability, and responsible AI usage.

- Stay updated on regulatory requirements for AI-driven manufacturing systems.

- Develop policies to ensure AI usage aligns with legal and ethical standards.

- Maintain clear documentation and reporting for AI-driven decision-making.

By following these structured steps, manufacturers can successfully integrate AI into their workflows, driving innovation, efficiency, and competitiveness in an evolving industrial landscape.

For expert AI solutions, OneGen offers tailored consulting and AI development services, ensuring seamless AI adoption and long-term success in manufacturing operations.

Ethical Considerations in the Deployment of AI Within the Manufacturing Sector

The deployment of AI in manufacturing raises ethical concerns that must be addressed to ensure responsible and fair usage. Transparency, accountability, and data security are critical for maintaining trust and compliance. Proactive ethical strategies help manufacturers leverage AI’s benefits while minimizing risks.

Bias and Fairness

AI systems can unintentionally reflect biases from their training data, leading to unfair outcomes. Manufacturers must ensure AI-driven decisions remain equitable, avoiding discrimination in automation and workforce management.

- Implement fairness-aware algorithms to detect and mitigate biases in AI models.

- Conduct regular audits to assess AI fairness and ensure compliance with ethical standards.

- Promote diverse data collection to train AI on unbiased, representative datasets.

Transparency and Explainability

AI decision-making processes often lack clarity, making it difficult to validate their outcomes. Ensuring AI systems are interpretable fosters trust among stakeholders and improves accountability in manufacturing operations.

- Develop explainable AI models that provide insights into decision-making processes.

- Maintain clear documentation to track AI-driven recommendations and predictions.

- Enable human oversight to review and challenge AI-generated outcomes when necessary.

Data Privacy and Security

Protecting sensitive manufacturing data is crucial as AI relies on vast amounts of proprietary information. Companies must implement robust cybersecurity measures to prevent data breaches and maintain operational integrity.

- Use strong encryption protocols to secure AI-driven data storage and processing.

- Establish strict access controls to restrict unauthorized use of AI-generated insights.

- Continuously update cybersecurity frameworks to address emerging AI-related threats.

Accountability

Manufacturers must take responsibility for AI’s decisions and their impact on employees, customers, and stakeholders. Clear accountability frameworks ensure ethical AI deployment and minimize risks associated with automation.

- Assign AI oversight teams to monitor and manage AI-driven processes responsibly.

- Establish protocols to handle unintended consequences of AI-driven decision-making.

- Ensure regulatory compliance by aligning AI usage with legal and ethical guidelines.

Regulatory and Industry Standards

Embedding AI ethics into legal frameworks ensures long-term compliance and fosters industry-wide trust. Manufacturers should collaborate with regulatory bodies to align AI applications with evolving policies and best practices.

- Work with industry organizations to develop AI governance frameworks and standards.

- Regularly update compliance policies to address new AI risks and ethical concerns.

- Engage external AI ethics experts to evaluate AI impact and recommend improvements.

By integrating ethical AI practices, manufacturers can deploy AI responsibly, balancing efficiency with accountability. A structured ethical approach strengthens AI-driven operations while safeguarding workforce rights and societal trust.

AI in Manufacturing: Essential Technologies and Methods

AI technologies are revolutionizing manufacturing through automation, real-time analytics, and intelligent decision-making. Machine learning, computer vision, NLP, robotics, and data analytics play crucial roles in optimizing production efficiency.

Machine Learning

Machine learning algorithms analyze vast datasets to identify patterns, improve production workflows, and enhance predictive capabilities. AI-driven insights enable manufacturers to minimize errors and maximize efficiency.

- Detect inefficiencies by analyzing historical production and maintenance data.

- Predict equipment failures to enable proactive maintenance and reduce downtime.

- Optimize resource allocation by forecasting demand and production cycles.

Computer Vision

Computer vision allows AI-powered systems to interpret visual data, automating quality control and defect detection. AI-driven image processing ensures precision in manufacturing, reducing waste and improving product consistency.

- Inspect production lines in real time to identify defects and maintain quality standards.

- Automate sorting and classification of materials based on AI-driven image analysis.

- Enhance worker safety by monitoring hazardous areas using AI-powered cameras.

Natural Language Processing (NLP)

NLP enables AI to process and understand human language, helping manufacturers extract insights from text-based data. AI-driven NLP tools improve customer interactions, equipment monitoring, and operational efficiency.

- Analyze customer feedback and maintenance logs to identify trends and performance issues.

- Automate documentation processing, reducing manual workload and improving accuracy.

- Enable voice-controlled AI assistants to support workers with real-time information.

Robotics

AI-powered robotics, particularly collaborative robots (cobots), enhance productivity by handling repetitive or hazardous tasks. These intelligent machines work alongside humans, increasing efficiency and ensuring workplace safety.

- Deploy cobots to assist workers in high-precision assembly and manufacturing tasks.

- Use autonomous robots for material handling, reducing human labor in logistics.

- Implement AI-driven robotic systems for adaptive and flexible manufacturing operations.

Data Analytics

AI-powered data analytics enables manufacturers to process vast amounts of operational data, providing actionable insights. Real-time data-driven decision-making enhances productivity, reduces costs, and streamlines supply chain management.

- Optimize inventory management by analyzing demand forecasts and production trends.

- Identify bottlenecks in manufacturing workflows and suggest efficiency improvements.

- Enhance supply chain visibility through AI-driven predictive analytics.

By integrating these AI technologies, manufacturers can unlock new levels of efficiency, precision, and automation, positioning themselves for long-term success in a competitive industry.

Advantages of AI in Manufacturing

AI is revolutionizing the manufacturing sector by enhancing efficiency, reducing costs, and optimizing production processes. By integrating AI-driven automation, predictive analytics, and intelligent decision-making, manufacturers can improve productivity, maintain high-quality standards, and gain a competitive edge in the market.

Boosted Efficiency and Productivity

AI-powered automation streamlines production by handling repetitive tasks with precision, reducing human errors, and ensuring consistent quality. This shift allows human workers to focus on more strategic and creative functions, improving overall operational efficiency. Additionally, AI-driven analytics provide real-time insights into production trends, helping manufacturers make informed decisions that enhance output and minimize downtime.

- Automates routine tasks, reducing manual errors and production delays.

- Enhances decision-making by analyzing real-time production and operational data.

- Improves workflow optimization, enabling manufacturers to meet growing demand efficiently.

Improved Quality Control

AI is transforming quality control by enabling real-time inspections, identifying product defects, and ensuring precision in manufacturing. AI-driven vision systems detect even the smallest irregularities that might be missed by human inspectors, significantly improving product reliability. By minimizing defects and reducing rework, AI helps manufacturers maintain high standards while reducing waste and production costs.

- Uses machine vision to detect defects with higher accuracy than human inspection.

- Reduces the need for manual quality checks, improving consistency and efficiency.

- Lowers material waste by identifying defects early, minimizing the need for rework.

Cost Reduction

AI-driven analytics optimize production processes, supply chains, and inventory management, helping manufacturers identify inefficiencies and cut unnecessary costs. By recognizing patterns in operational data, AI can predict bottlenecks, optimize resource allocation, and reduce energy consumption. This leads to streamlined operations, lower expenses, and improved profitability.

- Identifies inefficiencies in production, reducing unnecessary expenditures.

- Optimizes supply chain operations, minimizing waste and improving logistics.

- Reduces energy consumption through intelligent monitoring and automation.

Precise Demand Forecasting

AI leverages historical sales data, market trends, and external factors to produce highly accurate demand forecasts. This predictive capability helps manufacturers optimize inventory management, ensuring they produce the right quantity of goods to meet market demand while avoiding overproduction or shortages.

- Analyzes market trends and historical data to predict demand fluctuations.

- Reduces excess inventory costs by aligning production with customer needs.

- Improves supply chain efficiency, ensuring a steady flow of goods without disruptions.

Enhanced Safety

AI-driven collaborative robots (cobots) play a crucial role in improving workplace safety by handling physically demanding or hazardous tasks. These intelligent machines work alongside human employees, reducing the risk of workplace accidents and improving overall efficiency. AI-powered monitoring systems also enhance safety by detecting potential hazards in real time and alerting workers before incidents occur.

- Deploys cobots for high-risk tasks, minimizing worker exposure to hazards.

- Uses AI-driven sensors to detect safety risks and prevent workplace accidents.

- Enhances compliance with workplace safety standards through automated monitoring.

Instant Data Analysis

AI enables real-time data analysis, providing manufacturers with valuable insights into production performance, supply chain operations, and market trends. With AI-driven analytics, manufacturers can quickly identify inefficiencies, adjust operations, and respond to changes in consumer demand, ensuring maximum flexibility and resilience in a competitive market.

- Monitors production lines in real time, detecting inefficiencies and optimizing workflows.

- Analyzes supply chain data to improve logistics and minimize disruptions.

- Helps manufacturers respond swiftly to market changes, ensuring a competitive advantage.

Product Innovation

AI-powered data analysis helps manufacturers identify emerging trends, customer preferences, and potential improvements for existing products. This insight-driven approach accelerates product innovation, allowing companies to refine designs and introduce groundbreaking solutions that meet evolving consumer demands.

- Identifies market gaps and consumer needs through AI-driven analysis.

- Accelerates product development by streamlining design and testing phases.

- Enhances customization, allowing manufacturers to tailor products for specific customer preferences.

Optimized Supply Chain Management

AI-driven analytics optimize supply chains by evaluating vast datasets, including demand patterns, inventory levels, and supplier performance. By automating logistics planning and optimizing procurement, AI enhances overall supply chain efficiency, reduces costs, and ensures timely deliveries.

- Enhances inventory management by predicting demand fluctuations and reducing excess stock.

- Improves logistics efficiency by identifying optimal delivery routes and reducing delays.

- Strengthens supplier collaboration by analyzing performance data and mitigating risks.

Sustainability and Energy Efficiency

AI-driven energy management systems optimize resource consumption by continuously analyzing real-time data from manufacturing operations. By identifying inefficiencies and recommending energy-saving measures, AI helps manufacturers minimize costs and reduce their environmental impact, supporting sustainability initiatives.

- Optimizes equipment usage to reduce energy consumption and operational costs.

- Predicts energy demand and schedules tasks during low-energy cost periods.

- Supports sustainability goals by lowering carbon emissions and waste production.

By leveraging AI-driven technologies, manufacturers can significantly enhance productivity, improve product quality, and achieve sustainable growth. AI is not just a tool for automation—it is a transformative force that is shaping the future of manufacturing, making processes smarter, more efficient, and increasingly adaptive to changing industry demands.

Future Trends and Opportunities

AI is transforming manufacturing by enabling intelligent automation, predictive analytics, and real-time decision-making. As AI adoption grows, manufacturers will integrate emerging technologies like 5G, blockchain, and quantum computing to enhance productivity, supply chain resilience, and sustainability. Future advancements will further improve efficiency, flexibility, and innovation, leading to smarter, more adaptive production environments.

AI in Smart Factories and Industry 4.0

Smart factories use AI, IoT, and automation to create self-optimizing production systems that adapt in real time. AI enables predictive maintenance, automated quality control, and streamlined operations, minimizing waste and maximizing output.

- AI-driven digital twins simulate production environments, optimizing efficiency.

- Autonomous production systems detect and correct process deviations instantly.

- AI-powered supply chain analytics improve demand forecasting and resource planning.

Collaborative Robots (Cobots) and Human-Robot Interaction

AI-powered cobots enhance manufacturing by working alongside humans, performing repetitive, high-precision, or hazardous tasks. These robots improve workplace safety, productivity, and operational flexibility while reducing human workload.

- Cobots handle physically demanding tasks, reducing worker fatigue and injuries.

- AI-powered adaptability allows cobots to learn and refine tasks through experience.

- Seamless human-cobot interaction improves efficiency and workflow collaboration.

AI-Driven Decision Support for Manufacturing Executives

AI provides manufacturing leaders with real-time analytics, predictive insights, and strategic decision-making tools. By analyzing large datasets, AI-driven decision systems optimize operations, resource allocation, and risk management.

- AI enhances forecasting accuracy for production, inventory, and market demand.

- Real-time insights help executives make data-driven, proactive decisions.

- AI-powered risk analysis predicts disruptions and suggests mitigation strategies.

AI in Sustainable and Energy-Efficient Manufacturing

AI optimizes resource consumption, energy usage, and waste management, contributing to eco-friendly manufacturing. AI-driven automation supports green manufacturing by reducing carbon footprints and improving sustainability.

- AI-powered energy management systems lower consumption and operational costs.

- Predictive analytics optimize material usage, minimizing production waste.

- AI-driven sustainability insights ensure compliance with environmental regulations.

AI-Powered Predictive Maintenance and Asset Management

AI-driven predictive maintenance minimizes downtime and prevents costly equipment failures. By analyzing sensor data, AI detects potential issues before they cause breakdowns, ensuring seamless production.

- AI-based failure prediction reduces unexpected machine downtime.

- Intelligent maintenance scheduling maximizes asset lifespan and efficiency.

- Automated diagnostics help manufacturers address equipment issues proactively.

AI in Advanced Supply Chain Optimization

AI enhances supply chain efficiency by analyzing market trends, logistics data, and production needs in real time. AI-driven insights improve inventory management, reduce delays, and optimize procurement strategies.

- AI predicts supply chain disruptions and suggests alternative solutions.

- Automated logistics and inventory tracking ensure just-in-time manufacturing.

- AI-powered procurement systems optimize supplier selection and cost efficiency.

AI-Enabled Customization and Mass Personalization

AI allows manufacturers to create highly customized products while maintaining mass production efficiency. AI-driven design, flexible automation, and smart production lines enable tailored manufacturing.

- AI-driven design tools generate personalized product configurations at scale.

- Smart production systems adjust workflows to accommodate custom orders.

- AI-powered customer insights help manufacturers anticipate personalization trends.

The Future of AI Integration in Manufacturing

As AI continues evolving, its integration in manufacturing will drive next-generation smart factories with self-learning systems, adaptive production lines, and AI-managed supply chains. Innovations in AI-driven robotics, edge computing, and quantum-enhanced optimization will revolutionize manufacturing efficiency, agility, and sustainability.

Leveraging AI Agents for Optimizing Manufacturing Processes

AI agents are transforming manufacturing by automating decision-making, optimizing workflows, and ensuring efficiency. These self-operating systems analyze data, adapt to changing environments, and work collaboratively to enhance production quality and output. Their integration into manufacturing leads to improved accuracy, reduced waste, and more intelligent process management.

Types of AI Agents in Manufacturing

AI agents function in different capacities based on the needs of a manufacturing environment. They range from basic reactive models to advanced multi-agent systems that facilitate complex operations.

- Reactive AI agents: Respond instantly to real-time process data, ensuring immediate adjustments.

- Proactive AI agents: Predict future needs, optimizing scheduling, maintenance, and resource allocation.

- Multi-agent systems: Coordinate multiple AI units to manage production lines, robotics, and supply chains.

Applications of AI Agents in Manufacturing

AI agents optimize manufacturing operations by automating tasks, improving efficiency, and reducing downtime. They leverage real-time data to enable smarter decision-making and process improvements.

- Predictive Maintenance: AI agents analyze sensor data to detect potential machine failures, reducing unexpected breakdowns and maintenance costs.

- Production Optimization: These agents adjust schedules, resources, and workflows to enhance output while minimizing waste.

- Supply Chain Management: AI-driven forecasting improves logistics, inventory control, and supplier coordination for seamless operations.

- Quality Control: AI-powered visual inspection detects defects with high precision, reducing product recalls and customer complaints.

- Energy Management: AI-driven systems monitor and optimize power usage, lowering operational costs and promoting sustainability.

AI Agents in Process Optimization and Control

AI agents continuously analyze manufacturing data, adjusting key parameters like temperature, pressure, and speed in real time. This ensures consistent quality, efficiency, and cost reduction.

- AI-driven process automation minimizes human intervention, reducing errors.

- Continuous monitoring helps maintain production consistency and minimize material waste.

- Real-time optimization adapts to demand fluctuations and operational constraints.

AI-Driven Demand Forecasting and Planning

AI agents enhance demand forecasting by utilizing vast datasets, including market trends, sales history, and customer preferences. Their predictive capabilities help manufacturers align production with real-world demand.

- AI-based forecasts reduce overproduction, optimizing resource utilization.

- Data-driven insights improve supply chain coordination and prevent stock shortages.

- AI-powered planning adapts to external factors such as seasonal demand and economic trends.

Enhancing Manufacturing Agility with AI Agents

AI agents facilitate a more flexible and adaptive manufacturing environment. Their ability to integrate with robotics, IoT devices, and cloud computing enables rapid adjustments to changing demands and market conditions.

- AI-driven robotics autonomously adjust assembly lines to accommodate customized production runs.

- Smart AI-powered scheduling ensures efficient workforce and machine utilization.

- AI-enabled systems streamline order fulfillment by adjusting production flow based on real-time demand.

AI Agents in Human-Machine Collaboration

AI agents enhance collaboration between human workers and automated systems, improving overall efficiency. By working alongside employees, AI-driven assistants reduce workloads, improve decision-making, and enhance workplace safety.

- AI-powered virtual assistants provide operators with real-time guidance and recommendations.

- AI-enhanced safety monitoring reduces workplace hazards and ensures compliance with regulations.

- Human-in-the-loop AI systems allow workers to oversee and refine automated decision-making processes.

AI Agents for Sustainable Manufacturing

AI agents contribute to sustainability efforts by optimizing energy consumption, minimizing material waste, and enhancing environmental efficiency. Their role in green manufacturing is increasingly critical as industries focus on eco-friendly operations.

- AI-driven resource optimization reduces excess material use and energy waste.

- Smart waste management systems powered by AI improve recycling and disposal practices.

- AI-based carbon footprint tracking helps manufacturers achieve sustainability goals.

The Future of AI Agents in Manufacturing

AI agents will continue shaping the future of manufacturing, introducing more autonomous systems, self-learning algorithms, and AI-driven supply chain networks. The next generation of AI agents will lead to fully autonomous factories, real-time predictive decision-making, and seamless integration with emerging Industry 4.0 technologies.

Conclusion

AI is reshaping the manufacturing industry by enhancing efficiency, improving quality, reducing costs, and driving innovation. Its applications span across predictive maintenance, real-time quality control, supply chain optimization, and production planning, providing manufacturers with powerful tools to stay competitive in an evolving market. By leveraging AI, companies can streamline processes, minimize downtime, and adapt to changing demands, ensuring greater productivity and sustainability.

The future of AI in manufacturing is set to be even more impactful with the rise of smart factories, AI-driven robotics, and digital twins. These advancements will enable self-optimizing production lines, enhance human-robot collaboration, and improve decision-making through real-time data insights. AI-driven systems will allow manufacturers to achieve higher precision, automate complex workflows, and create safer, more adaptable production environments.

As AI adoption continues to grow, businesses must address challenges such as ethical considerations, data privacy, and workforce transformation. Investing in AI research, upskilling employees, and forming strategic partnerships will be crucial for seamless AI integration. Companies that embrace AI responsibly and proactively will unlock new levels of operational excellence, positioning themselves as leaders in the future of manufacturing.

Manufacturers looking to maximize efficiency, reduce operational costs, and enhance product quality should explore AI-driven solutions tailored to their needs. Contact OneGen today for expert AI consultancy and development services to revolutionize your manufacturing processes.

San Jose, CA - New York, NY